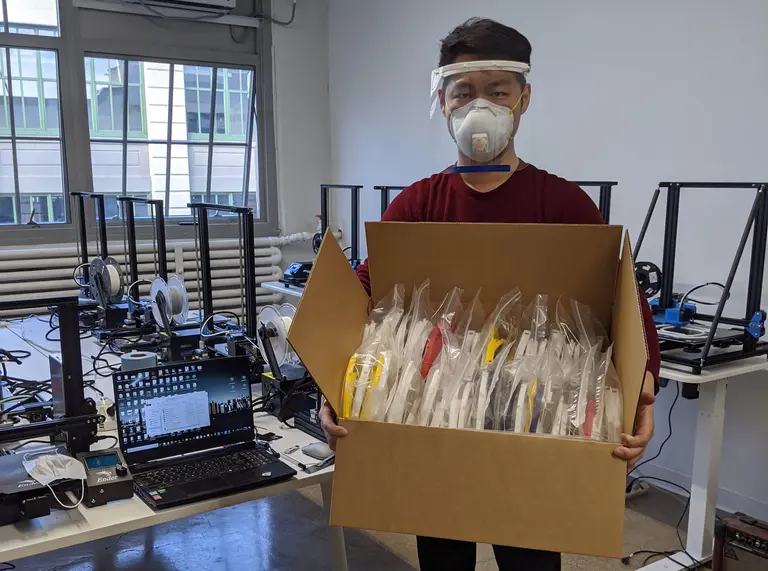

How this Brooklyn non-profit is producing 500,000+ isolation gowns for NYC hospitals

Photo courtesy of Course of Trade

As of this week, Industry City-based nonprofit workforce development organization Course of Trade has produced 219,279 hand-sewn isolation gowns for New York City hospitals, with an ultimate contract of 520,800 from the New York City Economic Development Corporation. Course of Trade was started by Malia Mills’ production director Libby Mattern to offer free sewing instruction and job placement assistance in the garment industry. When COVID hit the city, Libby knew it was time to innovate yet again, and she put in place a partnership with the city in which a 300-person team across South Brooklyn is sewing these life-saving gowns.

It all got started a couple of years ago when Libby when to Malia and presented her business plan for starting her own factory. After being given the green light, Libby found how hard it was to hire sewers and find people who could grow with the company. So she switched gears and developed Course of Trade as a nonprofit that teaches people to go into industrial sewing through a 120-hour training program. The true value of this initiative is that it doesn’t just teach people how to sit behind a sewing machine but it also teaches real-life skills like interviewing for jobs and opening a bank account. In conjunction, Malia Mills and Libby opened Course of Trade Manufacturing, which is the for-profit wing.

“When COVID hit, we were trying to figure out what two months or two days down the line looked like,” says Libby. So she reached out to the city and originally suggested that Course of Trade sew masks. But she quickly learned that isolation gowns were really what the city needed. “In the news, all you were hearing was masks and masks and masks, so it was cool to see that there was a need that we could fill.”

After setting up an official partnership with the Economic Development Corporation, Course of Trade mobilized four other main factories in South Brooklyn–That’s My Girl, MUDO Fashion, Custom Sewing Services, and the Fashion Poet–to shift their manufacturing efforts to making the critical PPE. All of these factories also subcontract to and manage smaller local factories, which adds another 15 roughly. In total, the group of factories is producing 65,000 patient isolation gowns per week to meet their total of providing 520,800 to New York City hospitals by the end of June.

Photo from Mayor de Blasio’s visit, via Flickr. Credit: Ed Reed/Mayoral Photography Office.

Libby tells us that Mayor de Blasio was instrumental in making the initiative happen, even helping to source the fabric, making calls to ensure it arrived, and visiting the Course of Trade factory. “He went to every single sewing machine, and he wanted to know the steps that were done on that sewing machine, what the next step was in the flow,” explains Libby. She also tells us that during his visit, several of the factory owners were present. “The factories so rarely get shoutouts. The designers are the ones who really are talked about, and really, nothing can happen without the people behind the sewing machines,” she said. Therefore, she found it especially moving and powerful when the mayor went around and gave each of the factories they accolades they deserve.

For Libby, one of the challenges in getting things up and running was that many of the people with the necessary sewing experience were in the vulnerable age group, so the team had to find people who felt safe working or could walk to work. “It’s a case in point for why we need workforce development in this sector. People don’t even know what great jobs sewing can be,” she said. “I think what this has really taught us is the importance of domestic manufacturing. It’s very empowering to be able to sit behind a machine and create something.”

Watch the Course of Trade factory in action here:

Video courtesy of Course of Trade

RELATED:

- Meet iMakr, the Brooklyn 3D-printer that’s made 5,000 face shields for NYC’s healthcare workers

- 40+ ways New Yorkers are helping healthcare workers

This interview has been edited and condensed for clarity.