Inside Casey Rubber Stamps: How this tiny rubber stamp shop has survived for 41 years in NYC

All photos © James and Karla Murray exclusively for 6sqft

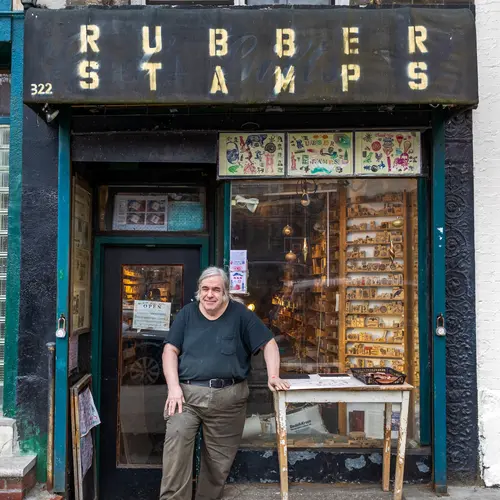

Tucked away on East 11th Street between First and Second Avenues is a small rubber stamp shop, which, according to the small sign in its window, is “closed when not open” and “open when not closed.” Casey Rubber Stamps is filled from floor to ceiling with rubber stamps that have all been handmade by John Casey and his two team members. John Casey is originally from Cork, Ireland and first founded his shop in 1979 on Seventh Avenue South in the West Village. He moved the shop to the East Village 19 years ago but still makes his stamps the old-school way with a negative, a plate, and a mold process that is both more time consuming and expensive than newer methods involving liquid polymer materials or laser cutting. Ahead, go behind the scenes to see how all the amazing rubber stamps are made, tour the interior and workspace, and learn about the shop’s history from John Casey.

The following is transcribed from an interview with John in his Irish brogue:

When I was a child, I was into collecting coins in a big way. My father owned a dance hall [in Ireland] and used to go to a print shop to get posters made, and they also made rubber stamps. They had an old printing block of a coin and they turned the coin into a rubber stamp. I thought it was so incredible that they could turn something so simple and reproduce the image so perfectly and with such detail, that it just appealed to me. I was only 13 years old, and here I am, many years later, still using that same process and being fascinated by it.

When I came to New York, I looked for that same old machinery used to make rubber stamps. When I finally found it, I opened up my rubber stamp store in 1979 and have been making stamps ever since.

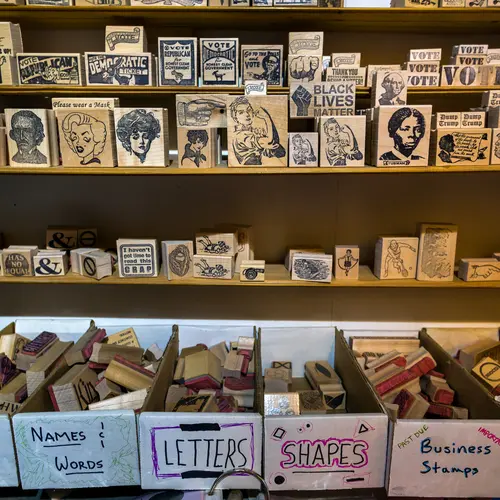

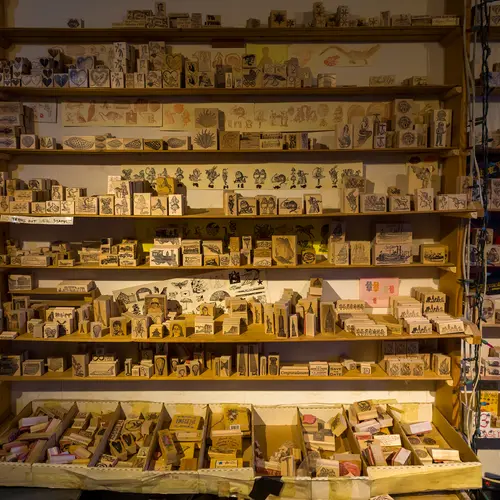

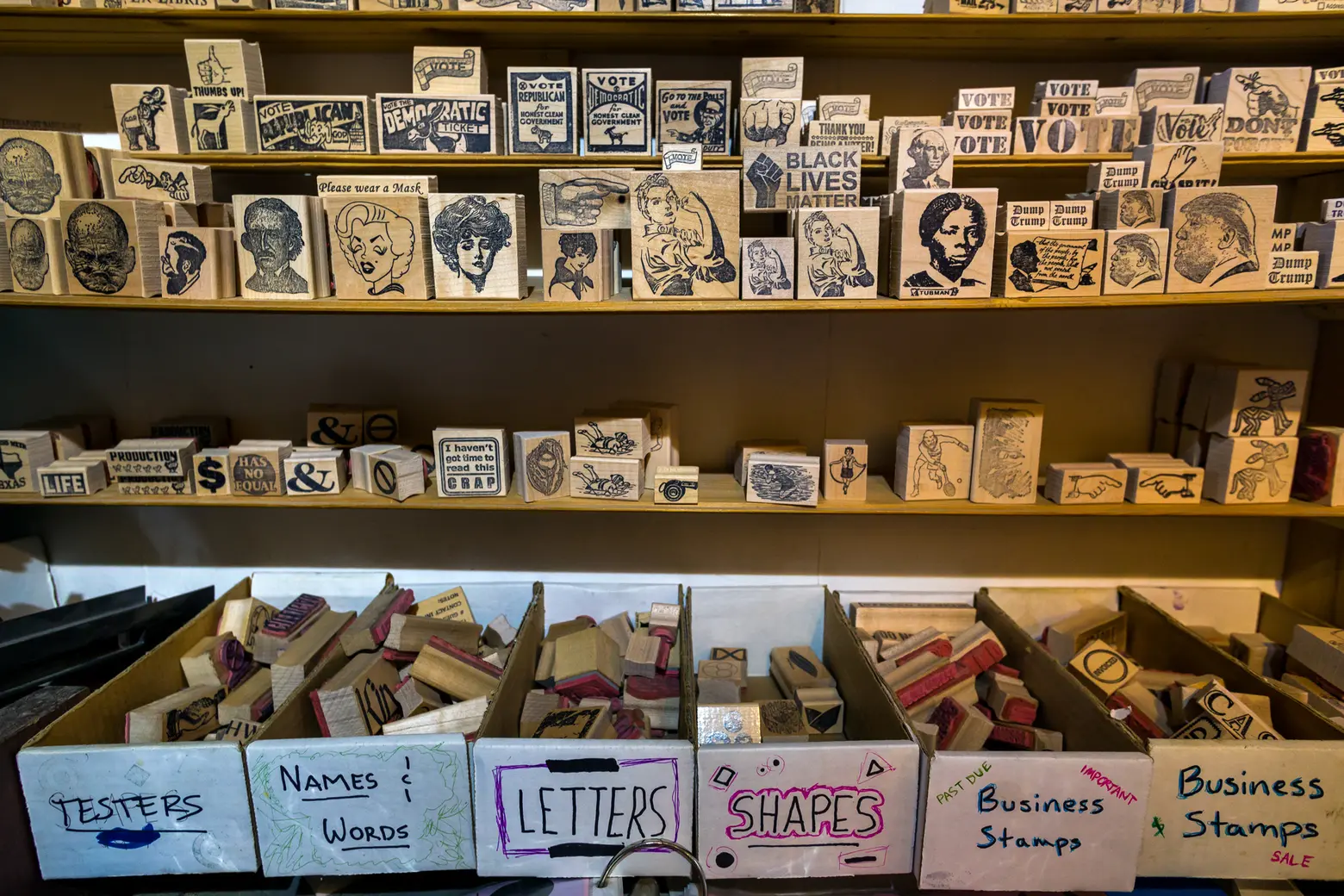

I have for sale over 10,000 designs which include everything from interesting letters of the alphabet, animals, floral designs, Victorian illustrations, postal and business themes, and even funny slogans. I looked through old encyclopedia books for illustrations that I thought would make a good stamp.

The most popular sellers include fancy lettering, hearts, skulls, and creatures.

We have lots of weird things that sell well. There are some surprise sellers including a NYC sewer cover, which I would never have judged as a good design to make a rubber stamp but somebody asked me for it, and then I just started selling it at the shop. Also, the match in the hand is a surprise seller, as well as the cat playing the sousaphone. I mean who the hell wants a sousaphone playing cat, but people love it!

The catalog I keep in the store has around 1,500 designs and I can make any of those stamps up immediately while you wait.

We also make custom stamps including logos, wedding invitation stamps, signatures, and even children’s drawings. A one-square-inch stamp costs only $20. The best advice I can give somebody who wants to order a custom stamp is that I need a good, sharp image. Line-art works really well, but I can also make a custom stamp from a photograph as long as I can extract the image to make a black and white rendering to turn into a stamp. We can do half-tones as well, but generally speaking, an etched work or an engraving makes wonderful stamps.

We can make rubber stamps up to an 8-inch x 10-inch size, but I advise people to stay within the size of our largest ink pad which is 4 x 7 inches for easier stamping. We sell about 40 different colors of ink pads, including waterproof ink pads for non-porous surfaces and fabric ink pads.

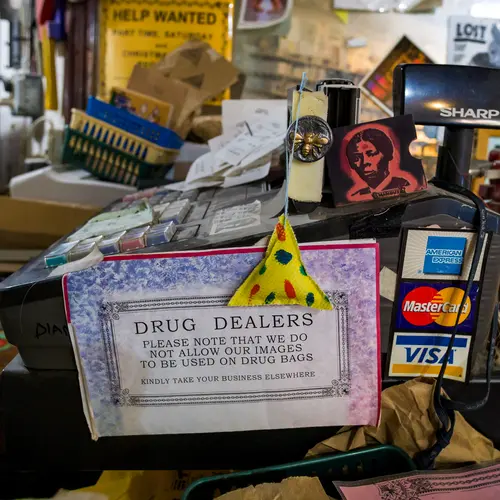

The one thing I don’t do is make drug stamps. One day a guy came in with a heroin bag and asked me to make a stamp for it and I said NO! So I made this sign I have posted on our wall by our cash register to discourage others from asking.

The old-school process I use to make my rubber stamps starts with me making a paste-up. Then I make a negative. The negative goes onto a sensitized plate. The modern plate is a metal-backed polymer, but in the old days, they used a plate of zinc or magnesium. The sensitized plate gets exposed to high-intensity UV light and gets hard and the rest gets etched and then washed away. When the plate is etched and dried and ready to go, we make a thermoplastic mold coated with Bakelite.

Using our Vulcanizer machine, the mold gets heated up and soft within 3 minutes. Then the mold gets squeezed onto a plate and after another 10 minutes, it’s hard and we remove the plate from the Vulcanizer machine. Then we put a sheet of rubber inside the machine. The rubber goes onto the mold at 307-degrees Fahrenheit for 10 minutes. It’s squeezed on and the heat solidifies the rubber, and through heat and pressure, we end up with a sheet of rubber with our stamp designs on it.

Then we cut out the individual designs by hand using scissors, and glue the stamp design onto custom-molded maple wood blocks and repeat the process for every stamp we make. We then stamp the design on the top of the woodblock so that everyone can identify which design is on their stamp.

In the past, my revenue was split pretty evenly between my custom design stamp work and the stamps I sell that are on display at the store. But my shop has been severely impacted by the Coronavirus pandemic. I had to close the shop to walk-in customers for a few months, and since I have reopened, business has been way down. There is NO tourist traffic, and tourist traffic was half of my business because I became a destination store. People would come to New York and visit the Statue of Liberty and the Empire State Building and MY SHOP to buy rubber stamps. The only reason I am still open is that I had some money saved. Otherwise, I would be out of business. I still have some regular customers including many graphic artists who just like the feel of a stamp in their hand and getting ink on their fingers, but walk-in customers are no more. Also because people are trying to set up small business enterprises of their own since they lost their jobs, they are ordering custom stamps. I am busy enough with custom orders but am still down from years past. Overall, I would say business is down 40 percent. Thankfully, my landlady has been good to me. I am here 19 years and the rent is relatively reasonable for the area.

The new modern methods used to make stamps by most commercial places are not as good. The stamps are plastic and made using liquid polymer or are laser cut, and I just don’t like them. They look great for the first month and then deteriorate rapidly. Rubber also holds ink much better than the polymer material, and the rubber stamps I make will last a very long time. In fact, I have rubber stamps that I made 30 years ago and you would not know that they were not made yesterday. Just make sure not to keep them in direct sunlight or near heat as that will destroy them.

I really appreciate a rubber stamp’s versatility because you can increase or decrease the pressure when you are stamping it with ink to get a whole different effect. For a very low-tech item, you can do a lot with it.

This interview has been edited for length and clarity.

To see even more of Casey Rubber Stamps, watch James and Karla Murray‘s Youtube video here:

RELATED:

- Where I Work: Inside Stephen Powers’ colorful world of studio art and sign making in Boerum Hill

- Behind the scenes at 95-year-old Woodhaven chocolate maker Schmidt’s Candy

- Where I Work: Mendel Goldberg Fabrics has been outfitting the Lower East Side for 130 years

All photos © James and Karla Murray exclusively for 6sqft. Photos are not to be reproduced without written permission from 6sqft.

+++

James and Karla Murray are husband-and-wife New York-based photographers and authors. Their critically acclaimed books include Store Front: The Disappearing Face of New York, New York Nights, Store Front II- A History Preserved and Broken Windows-Graffiti NYC. The authors’ landmark 2008 book, Store Front, was cited in Bookforum’s Dec/Jan 2015 issue as one of the “Exemplary art books from the past two decades” and heralded as “One of the periods most successful New York books.” New York Nights was the winner of the prestigious New York Society Library’s 2012 New York City Book Award. James and Karla Murray’s work has been exhibited widely in major institutions and galleries, including solo exhibitions at the Brooklyn Historical Society, Clic Gallery in New York City, and Fotogalerie Im Blauen Haus in Munich, Germany, and group shows at the New-York Historical Society and the Museum of Neon Art in Glendale, CA. Their photographs are included in the permanent collections of major institutions, including the Smithsonian Center for Folklife and Cultural Heritage, the New York Public Library, and NYU Langone Medical Center. James and Karla were awarded the 2015 Regina Kellerman Award by the Greenwich Village Society for Historic Preservation (GVSHP) in recognition of their significant contribution to the quality of life in Greenwich Village, the East Village, and NoHo. James and Karla live in the East Village of Manhattan with their dog Hudson.